In the early 1990s, architects and designers were pushing creative boundaries. They envisioned decorative, frameless glass walls and railings that could elevate interior spaces beyond standard construction materials. The problem? Industry limitations made these ideas nearly impossible to execute safely.

Many decorative art glasses could not be tempered. And without tempering, they could not meet the safety requirements necessary for structural applications like walls, railings, and partitions. Designers had the vision. The industry didn’t yet have the solution.

That changed in 1994.

That was the year Archetype Frameless Glass, Inc. was founded—and the year Decra-Lite was patented.

The Problem the Industry Couldn’t Solve

Before Decra-Lite, using decorative art glass in structural applications came with a major tradeoff: beauty or safety. You could have visually stunning glass, or you could have tempered safety glass, but you couldn’t effectively combine the two into a single, code-compliant panel for frameless installations.

Traditional laminating methods also fell short. Even when glass was laminated, the interlayer often stopped short of the edge, leaving vulnerabilities in durability and structural performance—especially in frameless systems where edges matter most.

Designers were forced to compromise. Archetype refused to.

The Decra-Lite Breakthrough

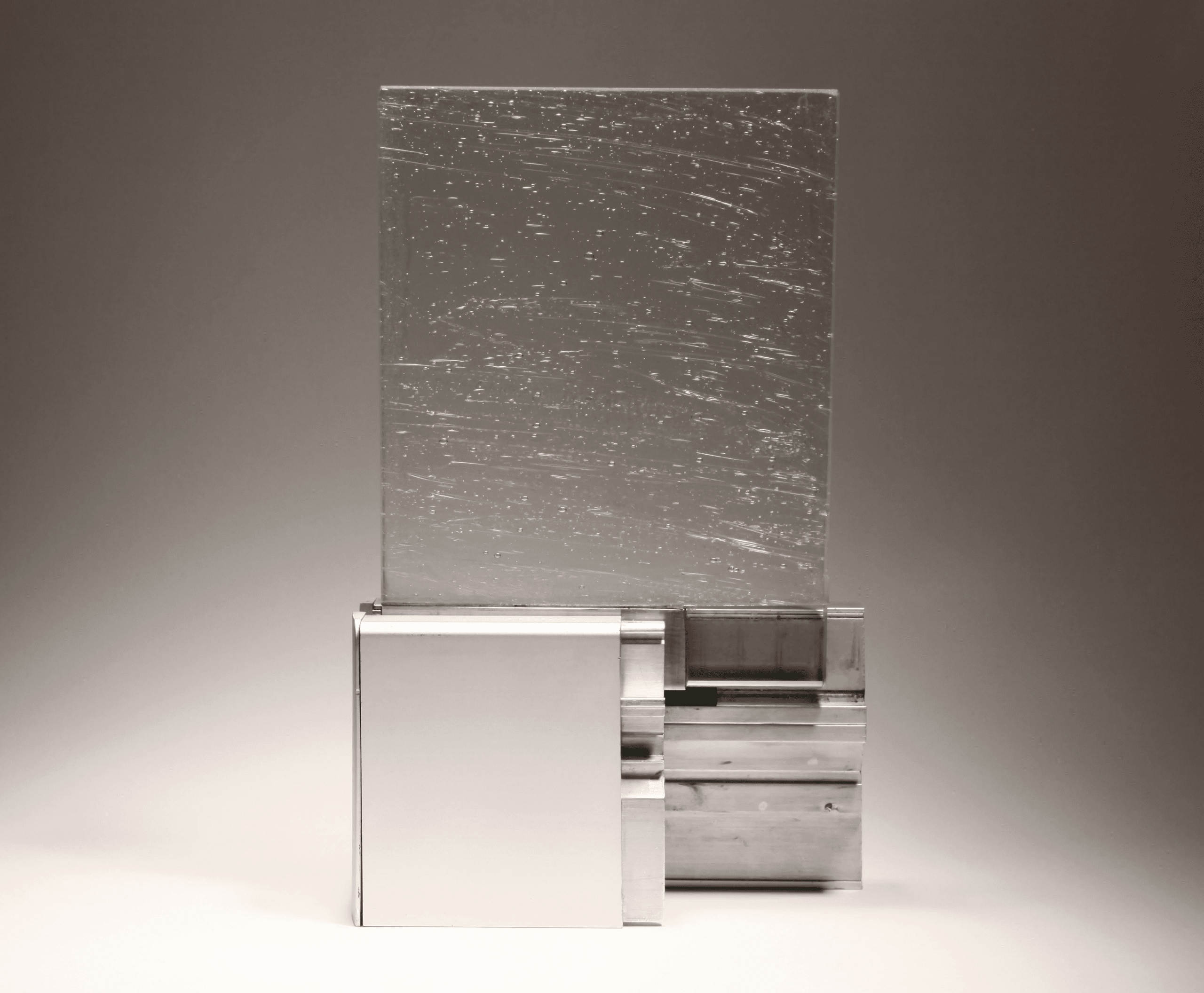

Decra-Lite introduced a patented system that redefined what was possible in architectural glass.

This system allows for:

- Tempered safety glass

- Decorative art glass

- A specialized pressure plate system

- A fully laminated panel where the laminate runs cleanly to the edge of the glass

By combining these elements into one cohesive system, Decra-Lite solved the industry’s biggest challenge: how to safely incorporate non-temperable decorative glass into structural, frameless applications.

The result was a glass panel that met safety standards without sacrificing design freedom.

Why Edge-to-Edge Lamination Matters

In frameless glass systems, the edge is everything.

When laminate does not extend to the edge, the glass is more susceptible to delamination, moisture intrusion, and structural weakness over time. Decra-Lite’s edge-to-edge lamination enhances:

- Structural integrity

- Long-term durability

- Safety performance

- Visual clarity and finish

The resulting product wasn’t just beautiful—it was engineered for real architectural use.

Unlocking Creative Possibilities for Designers

With Decra-Lite, architects and designers were no longer restricted by the limitations of traditional glass fabrication. Suddenly, decorative art glass could be used in:

- Frameless glass walls

- Railings and guardrails

- Partitions and feature installations

- High-end commercial and retail environments

Design intent no longer had to be redesigned to meet safety codes. The glass could now meet both.

The Foundation of Archetype’s Legacy

Decra-Lite wasn’t just a product. It was the foundation Archetype was built on.

From the very beginning, Archetype’s mission has been to solve the problems others consider unsolvable in architectural glass. Decra-Lite set that standard in 1994 and continues to influence how decorative laminated glass is used in modern design today.

What started as a solution to an industry limitation became a defining innovation that opened the door to entirely new possibilities in frameless glass architecture.

And nearly three decades later, the impact of Decra-Lite can still be seen in the most sophisticated glass installations across the country.

Because at Archetype, innovation isn’t about following standards. It’s about creating them.